CST has many years of experience working with a diverse range of composites and we only ever use the best quality materials. We have found that not only will higher quality materials give the customer better performance and longevity, it means that we can process these materials in a more efficient manner during the manufacturing process.

- Carbon: standard, intermediate and high modulus

- E-Glass

- S-Glass

- Basalt

- Kevlar/Aramid

| Fibre Type | Fibre Modulus | Composite Modulus | Elongation (Fibre Only) | Tensile Strength (Fibre Only) |

|---|---|---|---|---|

| Standard Modulus | 240 GPa | 100 GPa | 2.2 % | 5000 MPa |

| Intermediate Modulus | 280 GPa | 117 GPa | 1.9 % | 5660 MPa |

| High Modulus | 380 GPa | 159 GPa | 1.2 % | 4560 MPa |

| Ultra High Modulus | 550 GPa | 231 GPa | 0.7 % | 3970 MPa |

Resin Systems

- Epoxies

- BMI

- Specialty Resin Systems Proprietary to CST including fire resistant, high Tg and anti-static formulations.

Resin Development

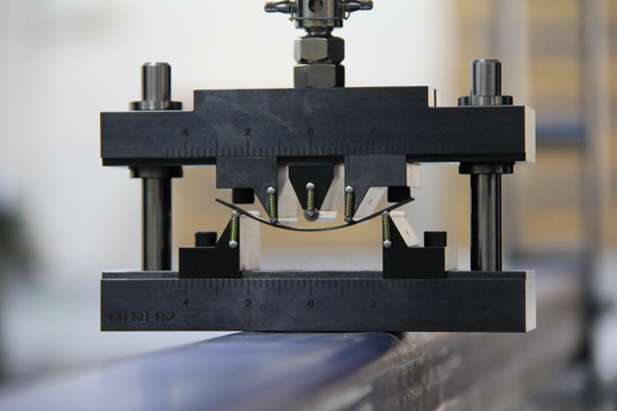

CST has its own in-house resin chemist to develop speciality resin systems to meet customers needs. To support this capability, our resin development laboratory houses the following equipment: Netzsche Polyma 214 Differential Scanning Calorimeter (DSC) for Tg characterisation, Microscopy with automated sample mounting and polishing, Instrom materials tester, Brookfield viscometer.

Batch tracking

All of our materials are batched during the production process using the CST Metrix™ proprietary software system.