The first part of the process is to come up with an overall rig layout within the rules. This will assist determining the overall mandrel geometry.

Choosing a one piece mast with no sleeving means that specific patching will be incorporated into the laminate for high load areas, reducing hard points and stress raisers.

We then generate a stiffness profile to suit the mandrel geoetry and mast layout.

Pattern design, optimises the laminate thickness vs stiffness vs toughness.

Patterns go direct from engineering to production floor winding machines, minimising human error.

FEA

With FEA models built to replicate the laminate schedule, a number of “What if” scenerios can be run to determine various bend profiles.

This provides sailmakers and sailors with an option to choose their preferred stiffness as well as bend characteristics.

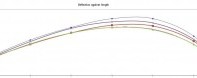

Model Vs Actual

Final step in the first article is to confirm actual results vs modelling.

With over 25,000 tubes made, the model predicts the bends within +-1%

Quality control reports show that the bend profiles of all masts are repeatable within +-2%

Rigged mast will be in the boat next week !