Point-loading is a carbon spars worst enemy. To prevent it, CST Composites are at the forefront of innovation. We are constantly striving to design better products. The latest product to emerge from the skunk works of our design and engineering facility is a new range of boom hangers to suit our various dinghy and skiff booms.

New Boom Hangers

These new fittings are the latest in our range of glue on fittings that eliminate the need to drill holes and fit bolts. When we make a product, we design it with very specific stiffness and strength characteristics. These numbers become less accurate as the carbon layup gets changed. An example of this change is drilling a hole. This severs strands of carbon which weakens the overall structure and alters the bend characteristics of the tube.

Point-loading is a major cause of breakages

Point-loading is a major cause of breakages

In order to combat this, we have been constantly upgrading our products, steadily altering fittings to eliminate the need for holes and improving our already established range of glue on fittings. These new design advancements are constantly producing better products, making them smaller, lighter, more robust, more versatile and stronger than ever before.

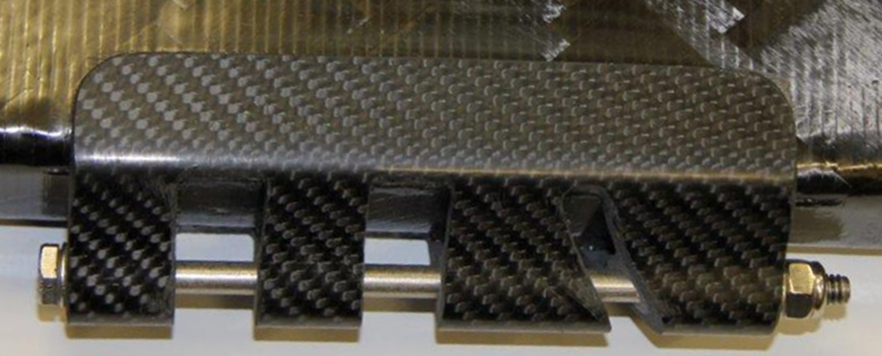

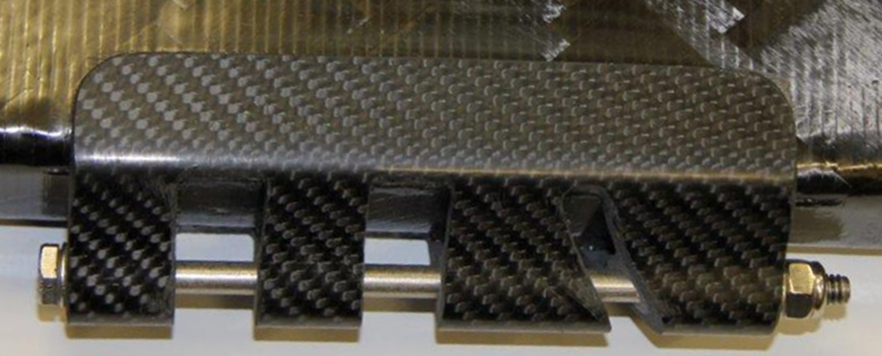

The latest glue on fittings are a set of boom hangers that are typically used for mainsheet blocks. This new fitting is incredibly strong, withstanding loads in excess of 1,200kg, but are also low profile, which is important when tacking a boat with a low boom height and also important to ensure block-to-block sheeting achieves the desired centreline boom position.

These hangers withstand in excess of 1,200kg

Glue on mainsheet hangers look slick

In addition, we have designed an incredibly simple product that makes it extremely easy to install yourself, and also incredibly easy to operate to replace blocks etc. This leads to another advantage of the glue on design which is the extremely high surface area contact. This spreads the load experienced by the fitting through a very wide area of the spar, vastly reducing the risk of failure. It also means that the fitting remains very securely attached as there is more surface to surface contact which improves cohesion.

This large surface area for loading is crucial to consider where carbon fibre products are concerned. The number one enemy of a carbon spar is point loading. This can occur through use of attaching fittings with bolts through the carbon product, or using a thin line around the tube with blocks attached to that. This presents a very small area of high load which can cause catastrophic failure of the carbon tube. This is where our glue on products come in, as the high surface to surface contact greatly reduces the risk of failure through reduction in point loading.