We went to Space! Kind of...

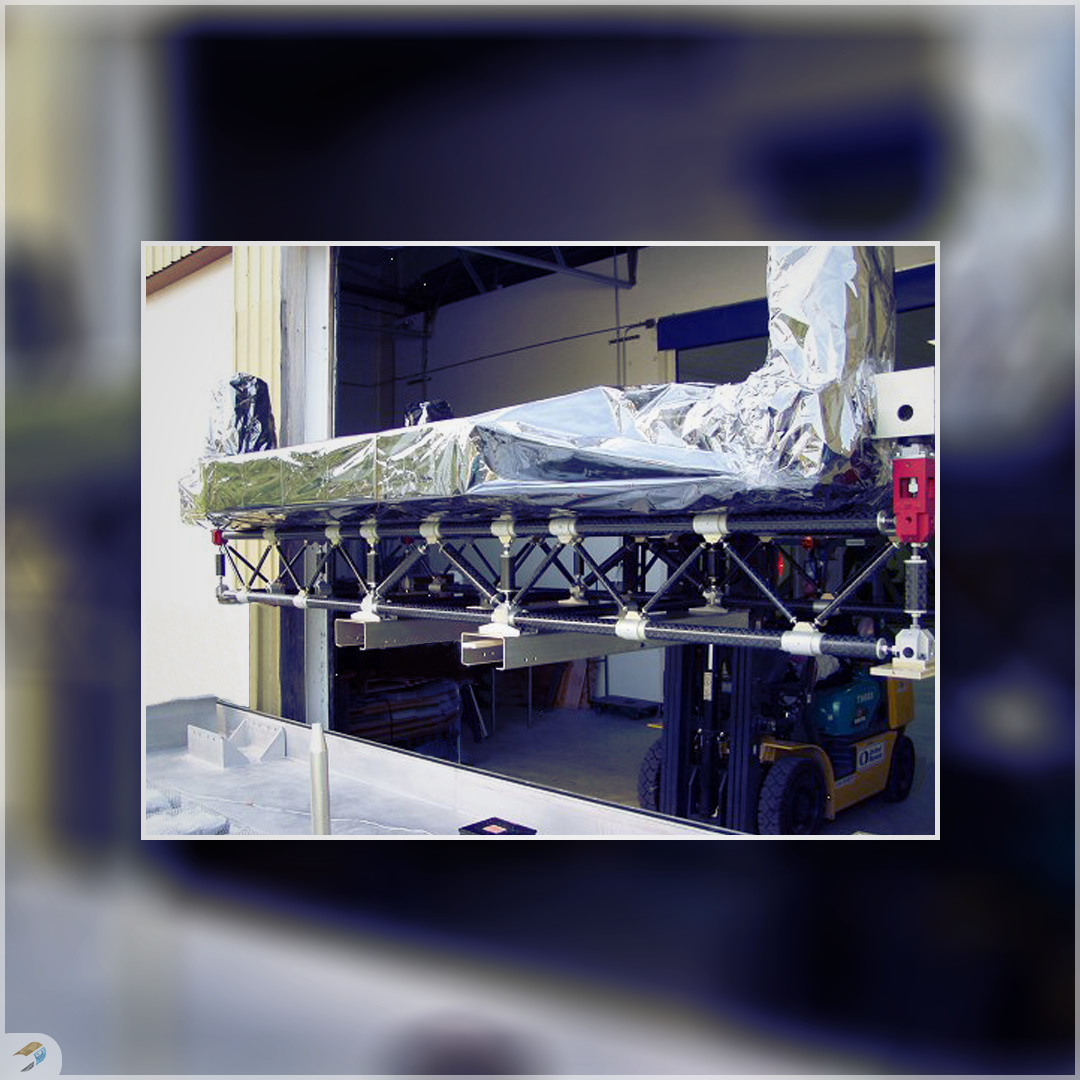

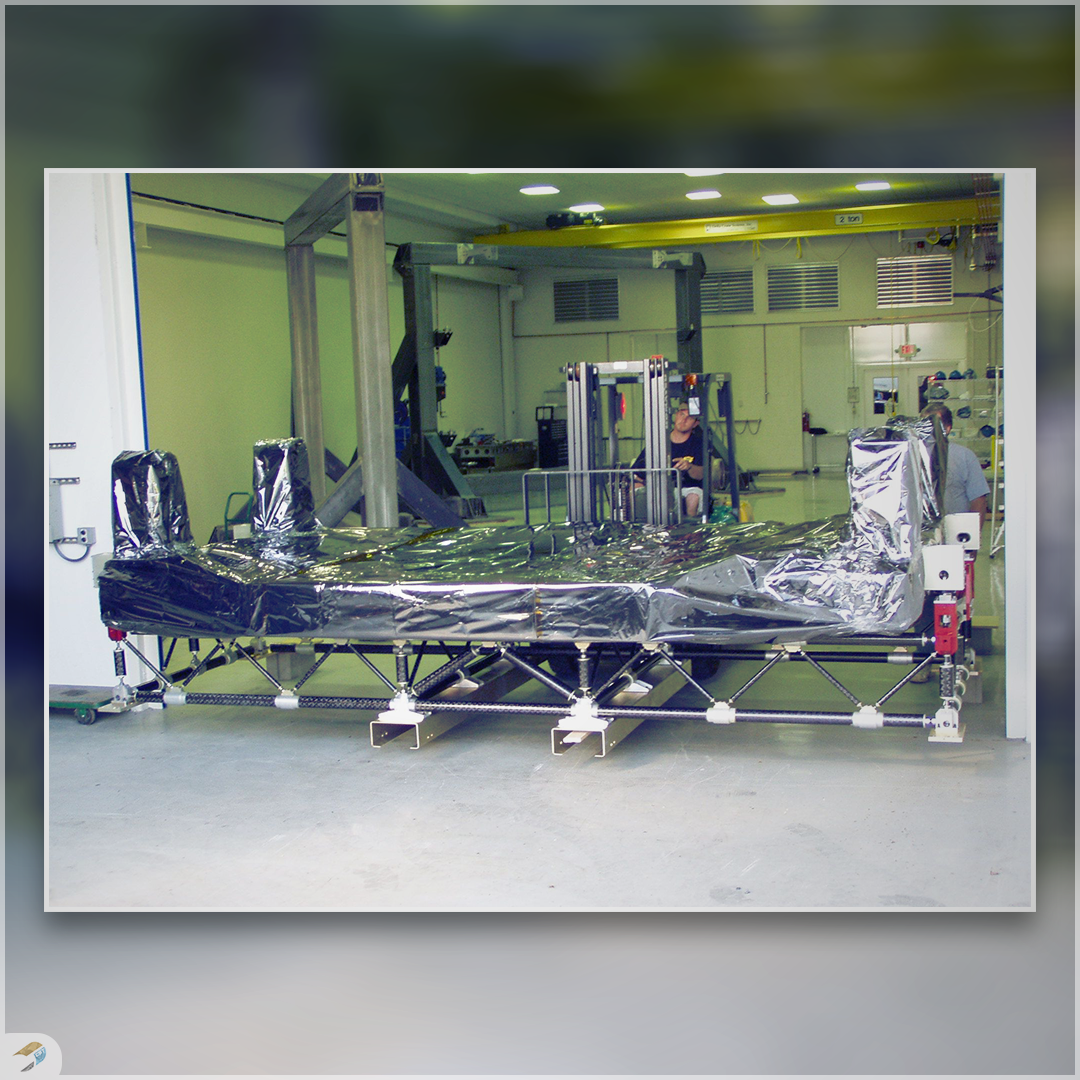

(NASA Hubble Telescope Cradle) - Flash Back Friday

In April 2005, CST received an urgent request from none other than Goddard Space Centre at NASA. That’s right NASA! The Hubble Telescope at the time was due for a refurbishment, replacing a Wide Field Planetary Camera for Service Mission #4. The problem was that they need a light weight but strong pallet to be mounted into the Shuttle Cargo Bay, which would hold the necessary equipment for the mission. To add even more pressure to the request, NASA needed the tubes in less than 6 weeks from the enquiry.

From the date of enquiry to the delivery in Florida, CST through our lean manufacturing techniques and engineering capabilities, was able to created specialized high modulus carbon filament wound tubes, all delivered in under 6 weeks to space centre.

Tom King, Senior Mechanical Engineer of ManTech International Corp. at NASA/Goddard Space Centre was very pleased with the support, delivery and quality of CST’s products. Going on to say, “This frame was used to handle & ship a flight pallet structure, called “SLIC”, that was used in the next Hubble servicing mission (aboard the Space Shuttle). By the way, it worked like a charm, and I thank you for your excellent technical support. We were all amazed at how strong the CST tubing was, and the build quality was phenomenal!!”

An in depth look:

The component that used the carbon fibre filament wound tubing was for a Horizontal Pallet (HP) Turnover Assembly. The HP was one half of the completed SLIC assembly, which was mounted in the shuttle’s cargo bay. As previously stated, the SLIC was used to carry a replacement Wide Field Planetary Camera to Hubble during Servicing Mission #4, alongside mission support equipment.

The Composite Backbone Assembly, which is where the carbon fibre tubes were used, is the frame structure used to support the HP during handling operations and transportation.

The structure was primarily made of graphite-epoxy tubing and machined aluminium fittings, bonded together with epoxy. The backbone had four corner fittings that attach to the HP MGSE brackets. The two attachment plates (shown in the images) connect to the bearing and gearbox assembly via shafts. The underside of the frame had a second set of four corner fittings for attachment to the transporter via wire rope isolators. In the mid-span of the frame, there are two fork “pockets” for fork truck operations