Available Soon!

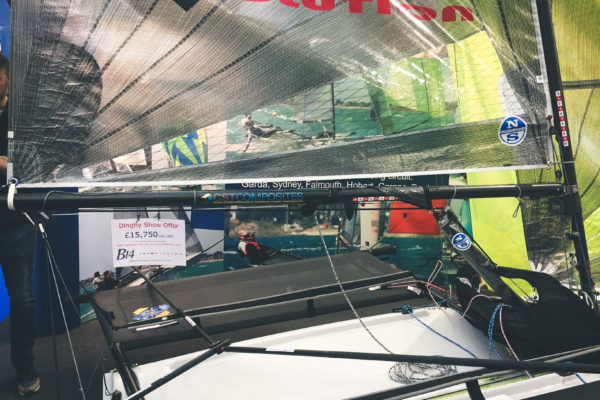

See the NEW TOWPREG masts in testing with Robert Greenhalgh

Behind the scene we have been quietly developing and testing the next generation of moth masts, taking the current DS and Elite range to the next level.

• Available for all Sail Brands

• New Tooling

• New Mast Attachments

• TowPreg material

• Precision machined joints

• Interchangeable Tips and Bases creating more options

Stay tuned for availability and release dates.