Winning a World Championship is a feat that many people can only dream of. But for Archie Massey and Dan Wilsdon of GBR1519, it seems to be a recurring theme. These amazing sailors managed to win the recent 2013 International 14 World Championship held at the Royal Canadian Yacht Club, notching up Archie’s 4th straight win and Dan’s 3rd straight win. Clearly these boys must have something that others don’t.

Their boat has been sporting a CST Composites rig and boom since they started winning World Championships and it has been paying consistent and clear dividends. The latest edition that they featured in this most recent Championship was our 125mm boom and HM 4 model mast. This is a one piece mast that offers many advantages over its two piece counterparts;

No sleeve in the middle of the mast means that the mast retains it’s even luff curve that presents the perfect glove to match the slick suit of sails from Dave Alexander Sails. The lack of a sleeve also reduces the weight of the mast, and other exclusive engineering advancements led to an overall weight reduction of 20% compared older models and competitors.

Not only has the mast slimmed down, it has been stiffened up. This provides a stiffer mast profile whilst still maintaining the automatic gust response tip which is so coveted by skiff sailors. This new design is perfectly suited to modern sails where the flat top mainsails are becoming bigger and more powerful in a class renowned for being at the forefront of speed increase technology.

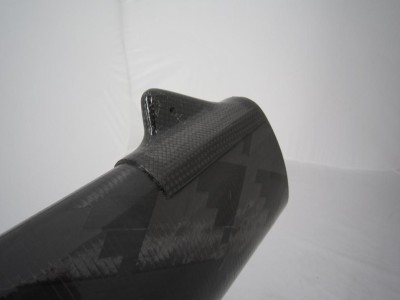

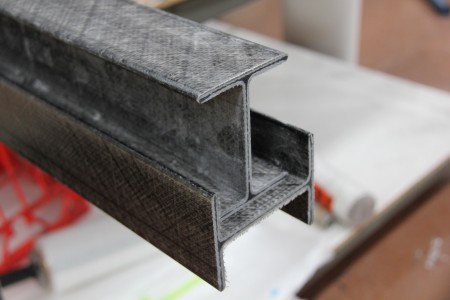

The HM 4 mast from CST Composites has been completely redesigned with speed in mind. Not only is this mast more suited to the constantly changing world of sail shape in the quest for speed, but it follows the recipe of “Lose weight to add speed”, including moulded spreaders to reduce drag, increase consistency and reliability whilst also keeping the kilograms to a minimum.